Have you ever wondered how aluminium extrusion processes can be streamlined for quick turnaround times, all while maintaining high standards of quality? At ALEXCO, we pride ourselves on delivering just that.

Our Story: Decades of Excellence in Aluminium Extrusion

Since 1940, ALEXCO has specialized in creating custom extrusion profiles with a commitment to quality and efficiency. Our integrated approach allows us to offer a comprehensive suite of services, from profile design and die manufacturing to extrusion, finishing, and even fabrication. This all-in-one model translates to faster, more precise results for our clients.

Comprehensive Services Under One Roof

Our facility brings together the expertise of various departments, all working in unison. This collaboration not only streamlines the production process but also allows us to offer tailor-made solutions to our clients. With everything in one place, we eliminate unnecessary delays, ensuring that your profiles are ready in days, not months.

Die Design & Manufacturing: Precision from the Start

A crucial aspect of our streamlined process begins with die design and manufacturing. By keeping this in-house, we can maintain stringent quality controls and significantly cut down on lead times.

Why In-House Die Design Matters

When we design and manufacture our dies in-house, it offers us the flexibility to quickly adapt to new requirements or modifications. This means less waiting for outsourced components and more control over the final product.

Fast-Tracking Your Orders

Thanks to our efficient setup, new profiles can be ready for extrusion in a matter of days. This swift turnaround is particularly beneficial for our clients who need quick prototypes or have tight project timelines.

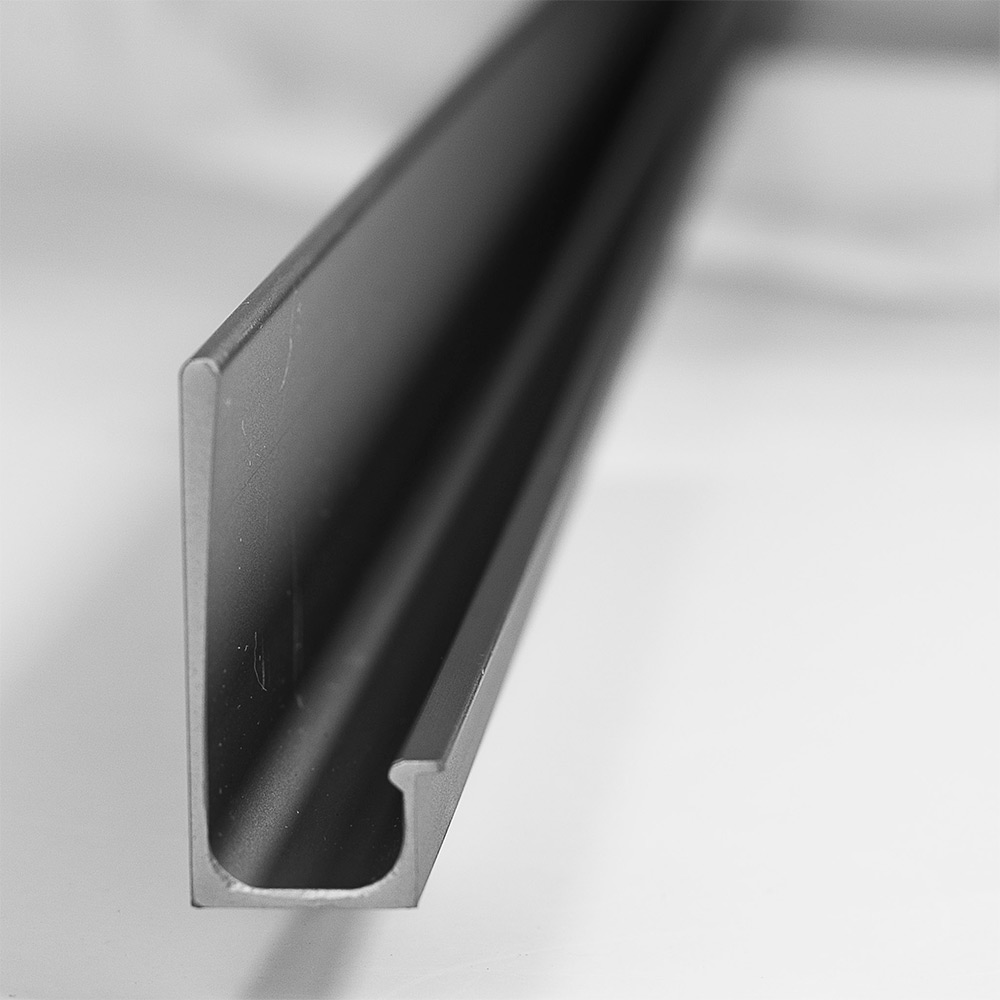

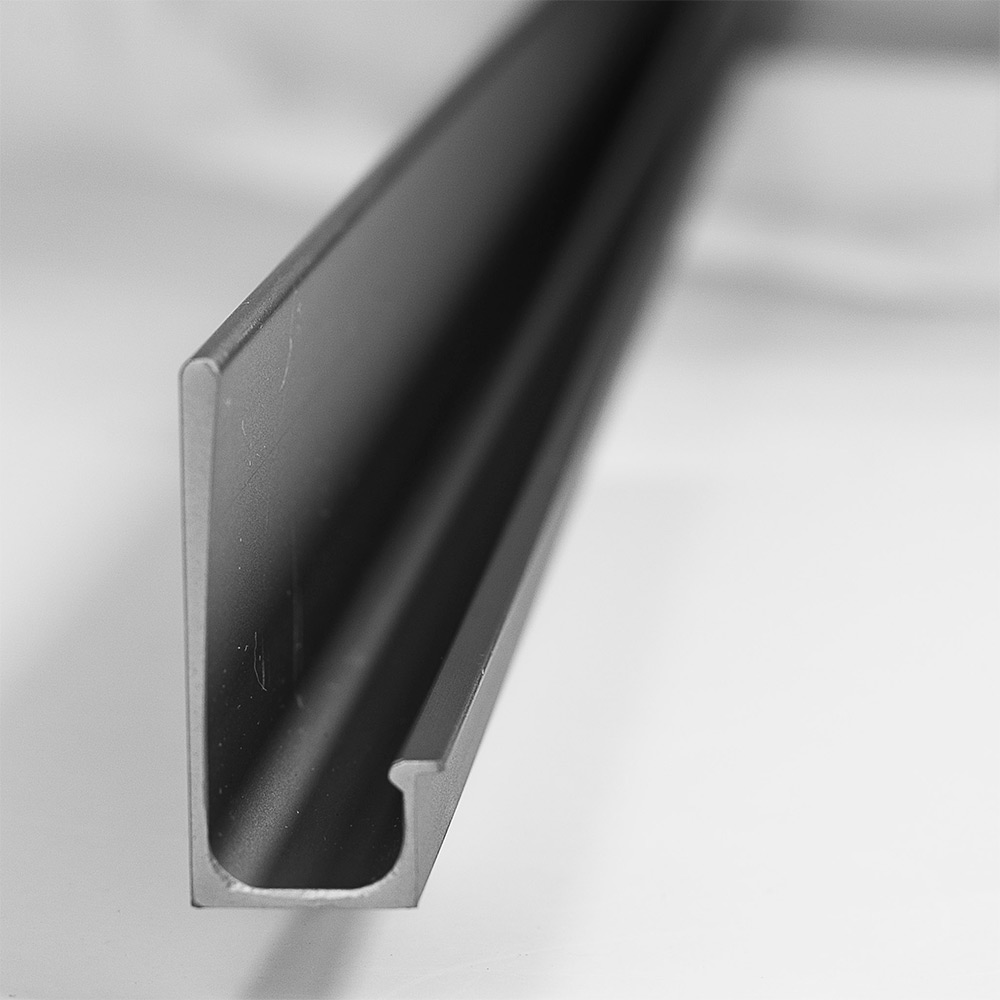

The Extrusion Process: Combining Precision and Speed

Our unique press sizes are designed to handle smaller profiles with higher precision. This combination is not just about meeting client specifications but about exceeding them.

Unique Press Sizes for Optimal Results

Our advanced presses are calibrated to deliver exceptionally accurate results, reducing initial setup costs. This makes smaller orders more feasible and ensures that we can accommodate a wide range of projects without compromising on quality.

Enhancing Accuracy

The precision of our equipment means that we can create intricate designs and tight tolerances, producing profiles that fit perfectly with your requirements. This high level of accuracy is a key advantage, especially for industries where exact specifications are critical.

One Team, One Roof: The ALEXCO Advantage

Our entire production team works under one roof, fostering better communication and coordination. This unified approach ensures that everyone involved in your project is on the same page, from initial design to final shipping.

Seamless Collaboration

By having our design, production, and quality assurance teams in close proximity, we can streamline decision-making and quickly resolve any issues that may arise. This cohesive teamwork results in a superior end product for you.

Direct Client Interaction

We believe in open communication with our clients. Being able to interact directly with our team ensures that your feedback is heard and implemented promptly. This approach not only builds trust but also leads to better project outcomes.

Diverse Fabrication Services for Every Need

Beyond extrusion, we offer a range of fabrication services to cater to various requirements. Whether you need custom milling, drilling, punching, or even retail packaging solutions, we’ve got you covered.

Custom Milling and Drilling

Our milling and drilling services allow us to create complex shapes and precise holes, tailored to your specifications. These capabilities are essential for industries like automotive, aerospace, and construction, where exacting standards are the norm.

Punching and Hardware Assembly

With advanced punching equipment, we can create detailed profiles with ease. Additionally, our hardware assembly services ensure that your profiles are ready to use right out of the box, saving you time and hassle.

Retail Packaging Solutions

We understand that presentation matters. Our retail packaging solutions ensure that your products arrive not just intact but also looking their best. From simple boxes to customized packaging, we cater to all your needs.

Quality Control: Our Commitment to Excellence

Every step of our process is governed by stringent quality control measures. We employ a variety of methods to ensure that each profile meets our rigorous standards.

Multiple Quality Checks

From the moment raw materials enter our facility to the final inspection before shipping, every profile undergoes multiple quality checks. This thorough approach helps us catch any discrepancies early, ensuring that you receive a flawless product.

State-of-the-Art Testing Equipment

We use advanced testing equipment to measure dimensions, check for defects, and validate the mechanical properties of our extrusions. This commitment to quality means you can trust our products to perform as expected.

Case Studies: Success Stories from Our Clients

Our streamlined aluminium extrusion process has yielded successful outcomes for a variety of industries. Let’s take a look at a couple of examples.

Automotive Industry: A Perfect Fit

A major automotive client needed high-precision profiles for a new line of electric vehicles. Our unique press sizes allowed us to deliver exacting specifications quickly. The collaboration resulted in faster assembly times and a more efficient production line for the client.

Aerospace Sector: Soaring Heights

For an aerospace client, the need for accuracy couldn’t be overstated. We designed and manufactured custom dies in-house and delivered profiles that met stringent aerospace standards. The quick turnaround enabled the client to meet tight project deadlines without sacrificing quality.

FAQs: Addressing Your Concerns

We often get questions about our process, lead times, and capabilities. Here are some of the most common inquiries.

How Quickly Can You Deliver?

Our streamlined process allows us to deliver new profiles in days rather than months. Specific timelines can vary based on project complexity, but our team is always transparent about expected delivery dates.

What Types of Aluminium Alloys Do You Use?

We work with a wide range of aluminium alloys, each suited for different applications. Whether you need high-strength materials or something more versatile, we can recommend the right alloy for your project.

Do You Offer Custom Finishes?

Absolutely. We provide various finishing options, including anodizing, powder coating, and mill finish. Each finish offers unique benefits and can be tailored to your specific needs.

Contact Us: We’re Here to Help

If you have questions about our services or need assistance with a custom extrusion profile, our team at ALEXCO is here to help. We are committed to offering detailed information, providing quotes, and offering expert advice tailored to your needs.

How to Reach Us

You can contact us at 04 388 1091, or visit our facility at 14 Southampton Road, Miramar, Wellington 6022. Our dedicated team is always ready to assist with your projects, ensuring you receive the best possible service.

Conclusion: Efficiency Meets Quality at ALEXCO

By keeping all our operations under one roof and employing a dedicated, cohesive team, ALEXCO transforms the complexities of aluminium extrusion into a straightforward, efficient process. Our commitment to rapid, precise, and high-quality production ensures that your projects succeed.

Streamlined processes, in-house die design, custom fabrication services, and a focus on quality control make ALEXCO the go-to choice for all your aluminium extrusion needs. Consider us your partner in transforming raw materials into the products you envision.