Have you ever wondered what goes into the making of high-quality aluminium extrusions? At ALEXCO, we believe in crafting excellence through precision and innovation, bringing all essential services under one roof to ensure seamless and efficient production.

ALEXCO: Engineering Excellence in Aluminium Extrusions

Our Story

Since our founding in 1940, ALEXCO has been dedicated to providing superior aluminium extrusion profiles and finishing services. We have built a legacy around quality and precision, making us a trusted name in the industry.

Our People

Our team comprises skilled artisans, engineers, and specialists who share a commitment to excellence. By working together closely on-site, we ensure that every project benefits from the collective expertise and attention to detail that define ALEXCO.

Comprehensive Services

At ALEXCO, our services span the entire production process, enabling us to deliver high-quality products promptly and efficiently.

Design: Crafting the Blueprint

Our in-house design services set the stage for excellence. By involving skilled designers and engineers early in the process, we ensure that each profile is tailored to meet unique requirements. This early collaboration reduces errors and enhances the final product’s quality.

Design Services Include:

- Die Design: Crafting precise dies that set the shape and standard for each extrusion.

- Die Manufacturing: In-house production ensures fast and accurate die creation.

- Die Profiles: Custom profiles tailored to specific project needs.

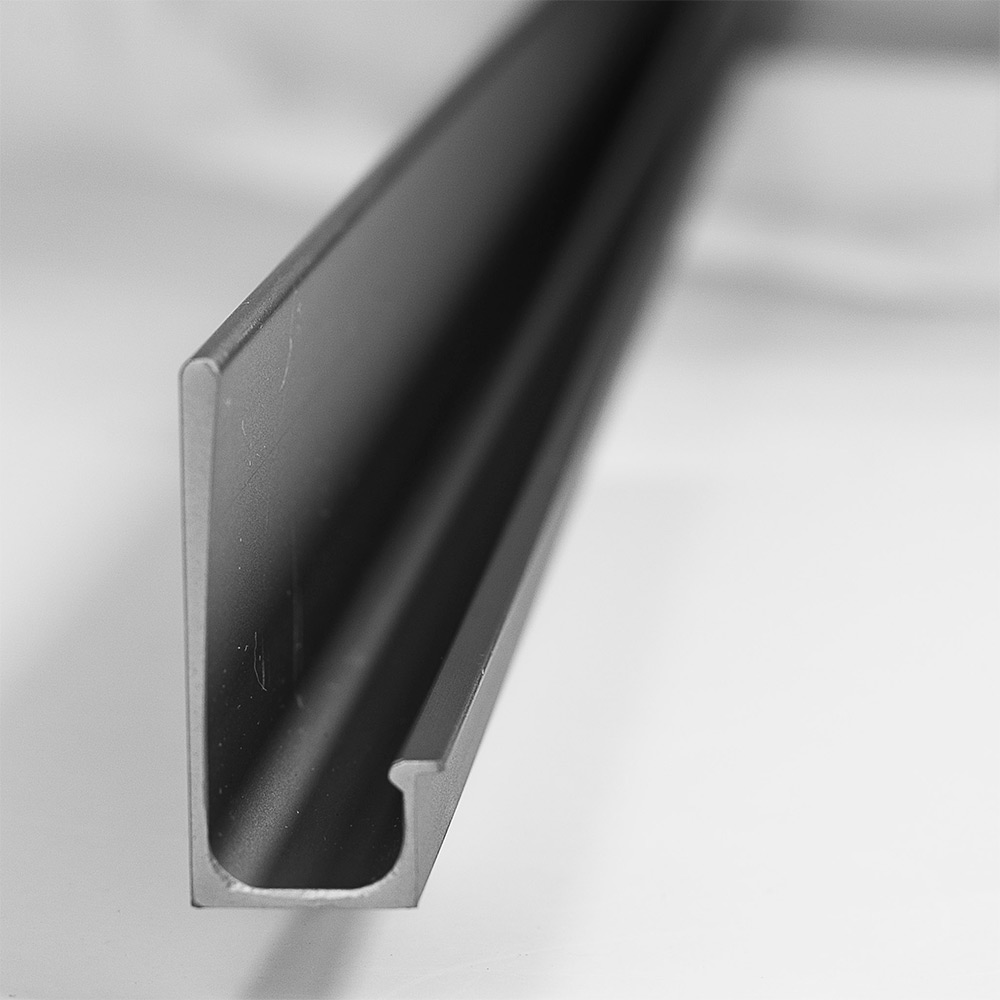

Extrusion: Where Ideas Take Shape

Extrusion is at the heart of our process. Utilizing advanced press sizes, we offer higher precision for smaller profiles while reducing initial setup costs. This capability is ideal for projects that require meticulous detail and are budget-conscious.

Extrusion Services Include:

- Production: Efficiently producing high-quality extrusions.

- Alloy Selection: Offering a variety of alloys to suit different applications.

- Temper & Tolerances: Ensuring that each extrusion meets the required strength and tolerance specifications.

- Cut Lengths: Providing custom cut lengths to match project specifications.

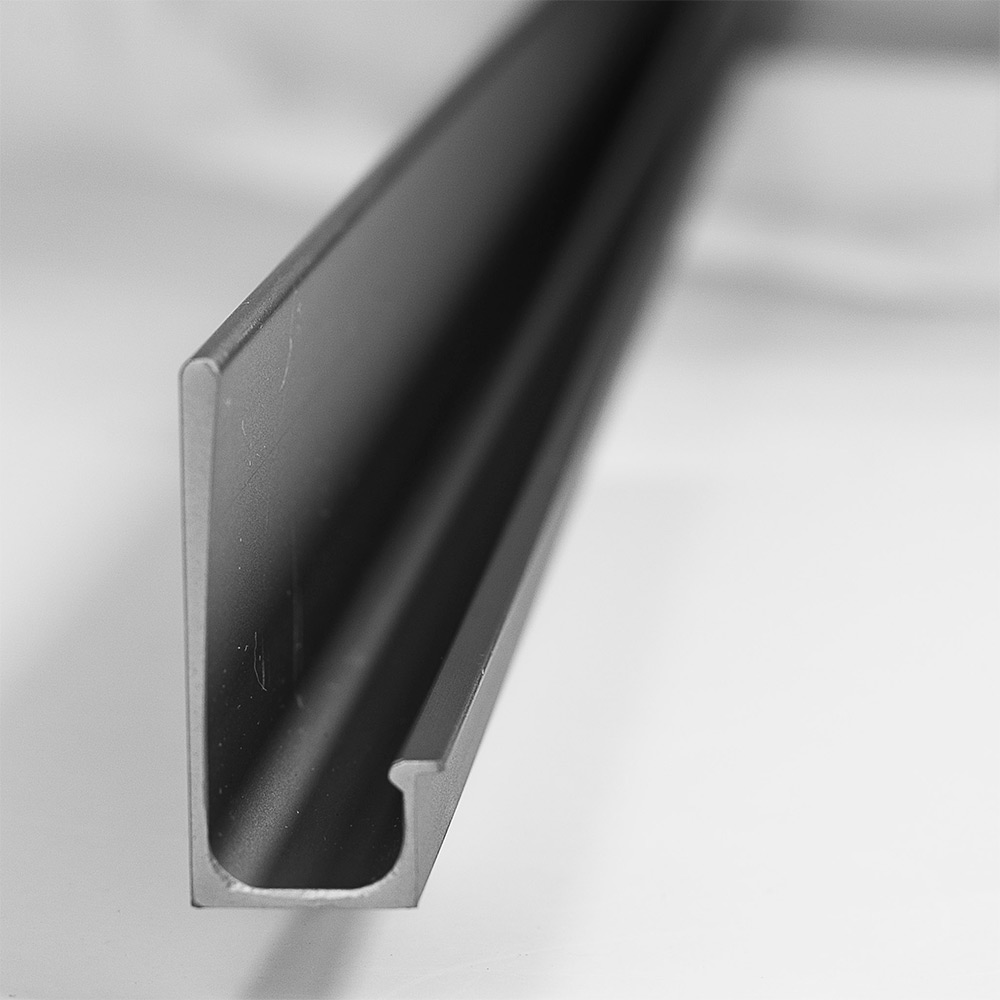

Finishing: Adding the Final Touch

Finishing is where our extrusions gain their aesthetic and functional qualities. We offer a range of finishing options to meet diverse needs, from enhancing durability to achieving a specific look.

Finishing Services Include:

- Anodising: Adding a protective oxide layer to enhance durability and appearance.

- Powder Coating: Offering a wide range of colors and finishes to suit various applications.

- Mill Finish: Providing a natural aluminum finish for a sleek, modern look.

Fabrication: Building Precision

Our fabrication services cover everything from basic modifications to complex assemblies, ensuring that each extrusion is ready for its intended use.

Fabrication Services Include:

- Milling: Custom milling to achieve precise dimensions.

- Drilling: Accurate drilling for seamless integration.

- Punching: Reliable punching for clean and smooth cutouts.

- Hardware Integration: Adding necessary hardware to complete the assembly.

Shipping & Fulfilment: Getting Your Product to You

Once the extrusions are ready, our shipping and fulfilment services ensure that they reach you promptly and in perfect condition. We handle everything from packaging to shipping, providing a hassle-free experience.

Shipping & Fulfilment Services Include:

- Packaging: Custom packaging solutions to protect your products.

- Shipping: Reliable shipping services to deliver your products on time.

One Site – One Team

Our entire production team operates under one roof, enabling unparalleled collaboration and efficiency. This cohesive environment allows for seamless communication and problem-solving, resulting in quicker turnaround times and higher-quality outputs. When you work with ALEXCO, you get to interact directly with the team crafting your solution, ensuring your vision is faithfully realized.

Specialised Extrusions and Quick Turnaround Times

ALEXCO’s approach to aluminium extrusion sets us apart from the competition. Our in-house die design and production allow us to streamline the process, ensuring that new profiles are completed in days, not months. This efficiency is vital for industries requiring rapid prototyping and quick market entry.

Key Advantages:

- In-House Die Design: Speeds up the production timeline.

- Precision Press Sizes: Achieves high accuracy for smaller profiles.

- Reduced Setup Costs: Makes smaller orders feasible and cost-effective.

FAQs about ALEXCO

What makes ALEXCO’s extrusion process different?

Our Streamlined end-to-end process, from design to shipping, ensures that your aluminium extrusions are manufactured with precision and speed. Our in-house die design and production capabilities allow us to control the entire process, reducing lead times and maintaining high-quality standards.

How quickly can I get my custom aluminium profiles?

Thanks to our efficient production process, we can deliver custom aluminium profiles in a matter of days. Our in-house die production and close-knit team collaboration ensure rapid turnaround times, significantly shortening the wait compared to traditional methods.

What alloys and finishes does ALEXCO offer?

We provide a wide range of alloys suited for various applications, each with specific characteristics such as strength, corrosion resistance, and malleability. Our finishing options include anodising, powder coating, and mill finish, each adding unique aesthetic and functional qualities to the extrusions.

Can ALEXCO handle small orders?

Absolutely. Our unique press sizes and reduced initial setup costs make smaller orders feasible and cost-effective. Whether you need a small batch of custom extrusions or a larger order, we are capable of accommodating your requirements.

Client Testimonials

We believe that the best endorsements come from those who have experienced our services firsthand. Here’s what some of our clients have to say:

John S., Manufacturing Director:

“Working with ALEXCO has been a game-changer for us. Their rapid turnaround times and high-quality extrusions have significantly improved our production efficiency.”

Samantha R., Product Designer:

“The collaboration with ALEXCO’s team was seamless. Their in-house design and fabrication capabilities meant we could iterate quickly and achieve the perfect profile for our needs.”

Contact Us Today

Have questions about our services or need assistance with a custom extrusion profile? Our team at ALEXCO is here to help. Whether you’re looking for detailed information, a quote, or expert advice, we’re just a call away.

Contact Information:

- Phone: 04 388 1091

- Address: 14 Southampton Road, Miramar, Wellington 6022

Conclusion

At ALEXCO, we’re more than just a manufacturing firm; we’re partners in bringing your vision to life. Our commitment to engineering excellence, coupled with our streamlined processes and top-tier team, ensures that your aluminium extrusions are crafted to perfection. With over 80 years of experience, we stand ready to meet your needs with speed, precision, and a dedication to quality that sets us apart.

So, the next time you think about aluminium extrusions, think ALEXCO—where engineering excellence meets efficient service. No project is too complex, and no timeline too tight for us to handle. Let’s build something great together.