How often do we find ourselves in need of high-quality aluminium extrusions with a quick turnaround? The demand for such precision and speed can stress even the most organized of us. This is where ALEXCO’s aluminium extrusion process comes into the picture, offering an efficient and swift solution for our needs. Since 1940, ALEXCO has specialized in providing comprehensive and high-quality aluminium extrusions and finishing services—all under one roof.

The Comprehensive Capabilities of ALEXCO

One Site: One Team

At ALEXCO, we bring all our services together in one location, creating a seamless and efficient process for aluminium extrusion. Our entire production team collaborates on-site, which means we’re able to interact directly with the individuals working on our solutions. This setup ensures streamlined communication and cohesive teamwork, leading to superior results and a faster turnaround.

From Concept to Completion

Our process begins with a thorough understanding of our requirements. ALEXCO’s experts guide us through each stage—from profile design and die manufacture to extrusion, finishing, and packaging. This end-to-end service model not only ensures consistent quality but also allows for rapid adjustments and refinements as needed.

Speedy Turnaround Times

In-House Die Design and Manufacturing

One of the key components of ALEXCO’s quick turnaround is their in-house die design and manufacturing capabilities. By keeping this critical aspect within the organization, ALEXCO eliminates the delays often associated with outsourcing. As a result, new profiles can be ready for extrusion in a matter of days rather than months.

Precision and Efficiency

ALEXCO offers unique press sizes that combine higher precision with the capability to handle smaller profiles. By enhancing accuracy and reducing initial setup costs, this aspect of their operation makes smaller orders viable, affordable, and swift to produce.

Seamless End-to-End Production

Our production is streamlined from start to finish with ALEXCO’s integrated approach. Their on-site collaboration allows for real-time problem-solving and innovation, ensuring that every stage of production is aligned with our expectations and timelines.

Collaboration and Communication

We benefit from direct interaction with ALEXCO’s team, fostering a collaborative environment where our feedback and requirements are heard and promptly addressed. This proactive communication model helps ensure that our project moves along smoothly and rapidly.

Detailed Breakdown of Services

Die Design & Manufacture

Creating high-quality aluminium extrusions begins with precise die design. ALEXCO takes pride in their in-house design and manufacturing processes, which expedite the production of new profiles. This advantage allows us to experience quicker turnaround times and more efficient operations.

Key Benefits:

- Fast turnaround for new profiles

- Enhanced accuracy

- Lower initial setup costs

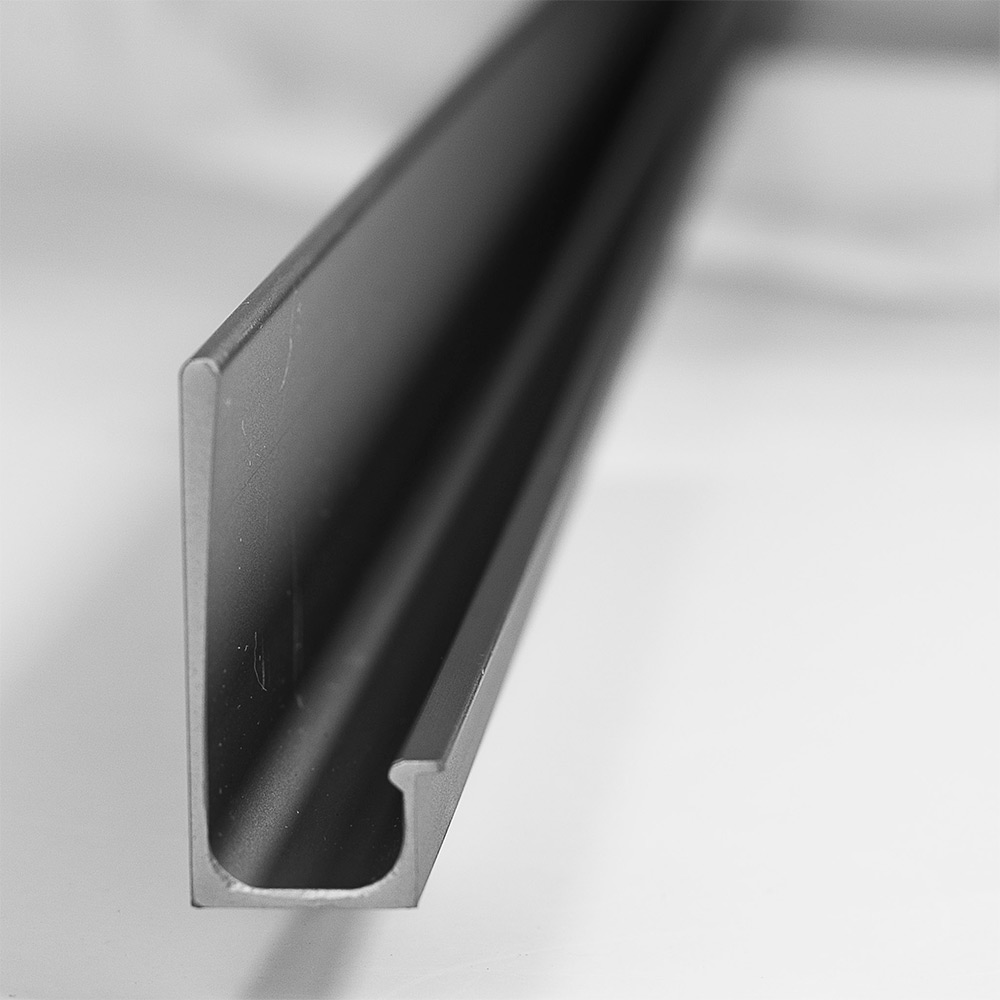

Specialised Extrusions

ALEXCO’s unique press sizes offer a noteworthy advantage when it comes to producing specialised extrusions. The higher precision capabilities make it feasible to handle smaller profiles, thereby ensuring our needs are met without unnecessary expense or delay.

Key Benefits:

- Enhanced accuracy for smaller profiles

- Cost-effective production for smaller orders

Fabrication Services

ALEXCO provides a comprehensive range of fabrication services, including custom milling, drilling, punching, and hardware integration. This broad spectrum of capabilities means we can trust ALEXCO to handle all aspects of our project under one roof.

Key Benefits:

- Comprehensive range of services

- Custom milling and drilling

- Punching and hardware integration

Finishing Services

Quality finishing is crucial for the durability and aesthetics of aluminium extrusions. ALEXCO offers various finishing options, including anodizing, powder coating, and mill finish. These services ensure our extrusions not only meet functional requirements but also attain the desired visual appeal.

Key Benefits:

- Multiple finishing options

- Enhanced durability and aesthetics

- Functional and visual quality

Retail Packaging Solutions

Once our extrusion profile is complete, ALEXCO also offers retail packaging solutions. This service ensures that our products are safely and attractively packaged, ready for shipment or immediate sale.

Why Choose ALEXCO?

Engineering Excellence Since 1940

ALEXCO’s long-standing history and specialization in custom extrusion profiles underscore their expertise and dedication to quality. This legacy of engineering excellence ensures we receive products that meet the highest standards of precision and durability.

Comprehensive Services Under One Roof

By consolidating all services—design, die manufacture, extrusion, finishing, fabrication, and packaging—under one roof, ALEXCO offers a streamlined and efficient process. This integration drastically cuts down on production time and enhances the quality of the final product.

Personalized Service

Direct interaction with ALEXCO’s team allows for a personalized experience. We get to collaborate closely with the experts, providing real-time feedback and receiving updates throughout the production cycle. This personal touch helps ensure our specific requirements are met.

Efficiency and Speed

ALEXCO’s in-house production capabilities—combined with their innovative use of unique press sizes—translate into faster turnaround times without sacrificing quality. This efficiency allows us to receive our products in days, not months, which is crucial for meeting tight project timelines.

The ALEXCO Experience

From Initial Contact to Final Delivery

When we reach out to ALEXCO, the process kicks off with understanding our specific needs. Their knowledgeable team is always ready to assist, whether we’re looking for detailed information, seeking a quote, or needing expert advice on a custom extrusion profile.

Detailed Consultation

During the consultation phase, ALEXCO’s experts delve deep into our project requirements. This comprehensive understanding assists in crafting a tailored solution that aligns precisely with what we envision.

Design and Die Manufacturing

The design and die manufacturing phase is where our concept begins to take physical form. With ALEXCO’s in-house capabilities, the transition from idea to prototype is quick and seamless.

Quick Extrusion and Finishing

Upon completing the die, the extrusion process commences. ALEXCO’s unique press sizes come into play here, ensuring high accuracy and reduced setup costs. Following extrusion, the finishing stage adds the final touches, whether through anodizing, powder coating, or mill finishing.

Quality Checks and Packaging

Before our product leaves the facility, it undergoes rigorous quality checks to ensure it meets all specified criteria. Finally, ALEXCO’s retail packaging solutions guarantee that our products are securely packaged and ready for their destination.

Delivery and Post-Production Support

ALEXCO’s commitment to excellence doesn’t end at delivery. Their team remains available for any post-production support or inquiries, ensuring a satisfying and complete customer experience.

ALEXCO’s Services: A Snapshot

To make it easier to understand the range of services ALEXCO offers, the following table breaks it down:

| Services | Key Features | Benefits |

|---|---|---|

| Die Design & Manufacture | In-house design and manufacturing | Quick turnaround, enhanced accuracy |

| Specialised Extrusions | Unique press sizes for high precision | Cost-effective production, feasible small orders |

| Fabrication Services | Custom milling, drilling, punching, hardware integration | Comprehensive service range, one-stop-shop |

| Finishing Services | Anodizing, powder coating, mill finish | Enhanced durability, aesthetic quality |

| Retail Packaging | Packaging solutions for ready-to-ship products | Safe, attractive packaging |

Final Thoughts

At ALEXCO, we find a partner dedicated to delivering high-quality aluminium extrusions swiftly and efficiently. Their integrated services, from die design to retail packaging, provide a streamlined process that ensures our needs are met precisely and timely. By maintaining all services under one roof, ALEXCO eliminates delays, enhances communication, and ensures that the final product meets our exact specifications.

Choosing ALEXCO means opting for engineering excellence honed over decades, detailed and personalized service, and a commitment to efficiency and speed. Whether we’re embarking on a new project or converting existing profiles for production, ALEXCO proves to be a reliable and invaluable partner in our endeavours.

If you have any questions about ALEXCO’s services or need assistance with a custom extrusion profile, their team is just a call away. For us, partnering with ALEXCO ensures our projects are handled with professionalism, expertise, and expediency—a combination that guarantees success.