Explore our specialist aluminium extrusion and finishing services; from concept design through to retail packaging and shipping.

Our Expert Services

Die Design

At ALEXCO, we are unique in our ability to design and manufacture dies in-house on one site – the only extruders in NZ who can run end-to-end design to production

With our experienced team; we work with our customers to fully understand the function of the extrusion and assist them towards a solution that will fit their purpose. Die manufacturing costs vary based on complexity and tolerances.

Our design team includes Architectural, Engineering and tool making experience and with over 40 years of in-house expertise, there’s little we haven’t mastered.

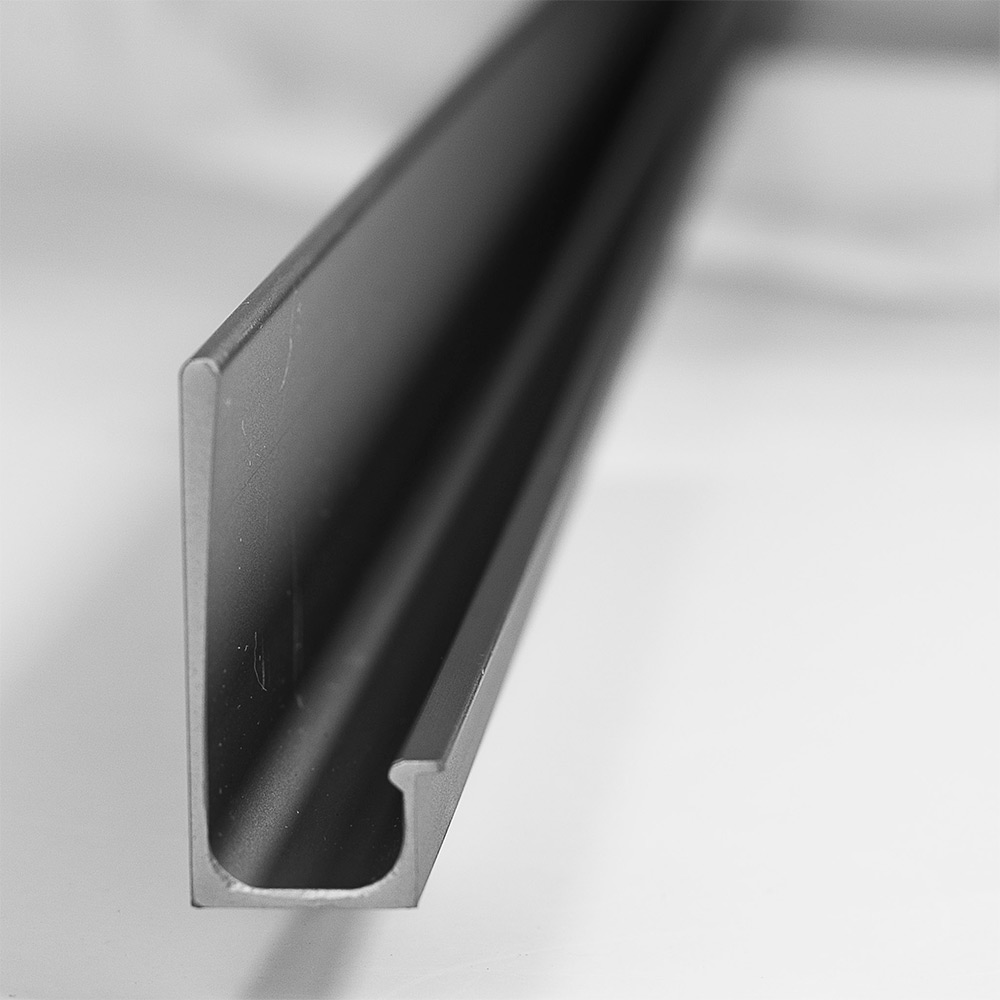

Extrude

Our unique press size enables us to manufacture smaller profiles compared to other NZ extruders. This gives us the advantage of achieving a higher level of precision, which significantly reduces initial setup costs and makes smaller orders feasible.

Our standard lead time for mill finish profiles is typically 10 days, while powder coated or anodised finishes may require 15 days. However, feel free to reach out to us; we’ll do our best to assist you if you’re facing production constraints.

We specialise in small runs eg: less than 150kg, and because we have a fully automated line and all on one site, we are efficient and easy to deal with.

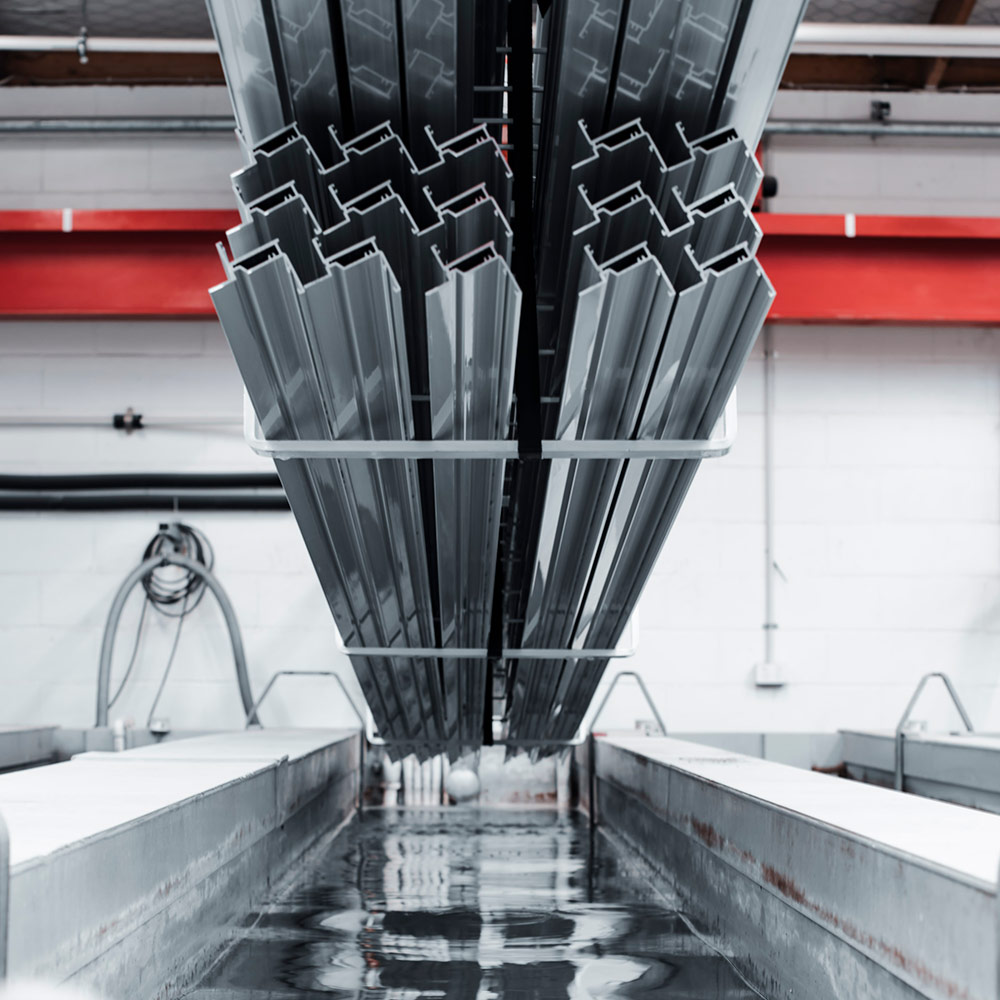

Finish

We have three core finishing capabilities, which are fully automated lines, integrating our capabilities on one site:

Powder Coating

Anodising

Mill Finish

Fabricate

We can shape, cut, bend or assemble components based on your designs and requirements, with ALEXCO’s onsite team.